EPS Resin Processing

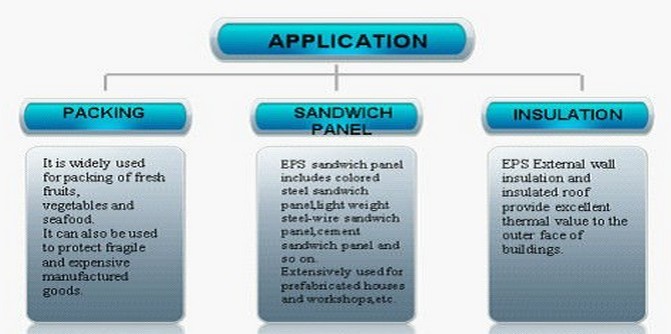

EPS resin is EPS raw material used for the moulding of EPS products like package, food containers and building insulation.

EPS resin is manufactured in the form of very small polystyrene beads with a weight weight between 160,000 and 260,000 and contains 4% to 7% blowing agent, usually pentane or butane. The bead diameter vary between 0.007 inches ~ 0.11 inches (0.2mm ~ 3.0 mm).

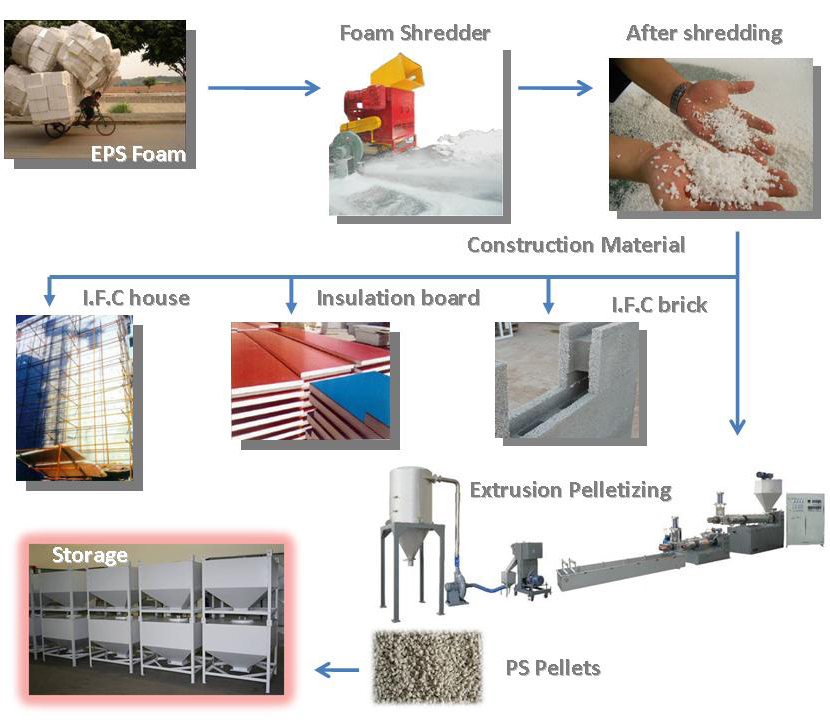

Here show the sheet of EPS resin processing:

EPS Resin Polymerization and Impregnation

The first methods developed involved two step process; polymerization of styrene monomer followed by impregnation of the polymerized polystyrene bead with a blowing agent.

Today, almost all processes carry out polymerization and impregnation in one step process. The reaction occurs in a single reactor designed to control the temperature and pressure of the reaction.

Styrene monomer and water is charged to the reaction kettle equipped with an agitator. Various chemicals are added to affect suspension of the monomer in water and to control the polymerized bead growth, molecular weight and other parameters necessary to produce the desired product. The polymerization is an exothermal reaction and is controlled by reactor temperatures and pressures, as well as various catalysts.

In the second phase of the process, the blowing agent is added under pressure and impregnates the soft polystyrene beads. The total batch cycle takes a little less than twelve hours. When completed, the entire batch consisting of water and the impregnated polystyrene beads are dumped to de-watering systems.

EPS RESIN operation finished

Following the de-watering process, the polystyrene beads are transferred to dryers for drying. The conditions used to polymerize the polystyrene beads play a controlling part in determining the exact shape and or skew ness of the particle size distribution. The dried polystyrene beads are then screened through state-of-the-art systems to provide the desired size cut. Various surface lube system are added at this point prior to packaging eliminate potential lumping during pre-expansion.